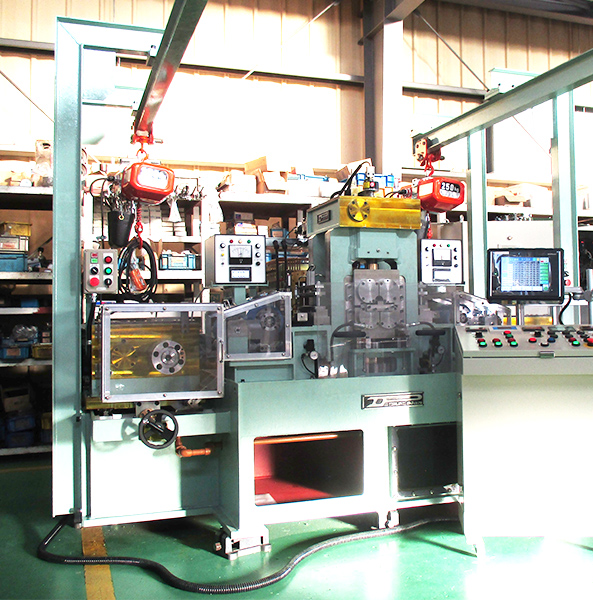

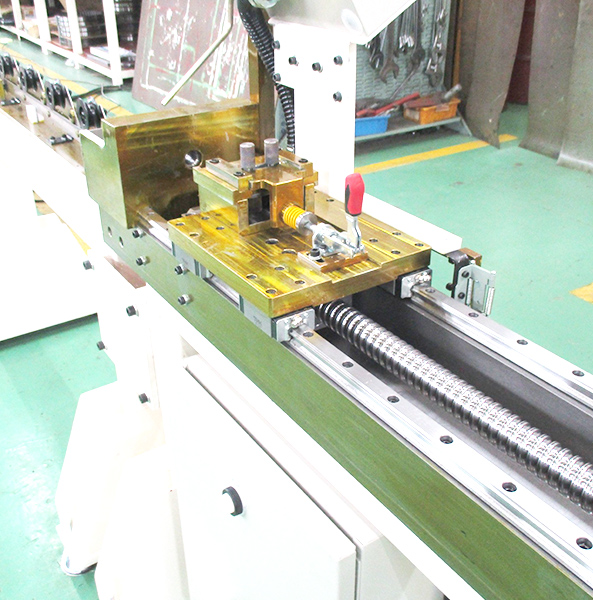

Product 01板圧延機

被圧延材幅寸法350[mm]以下、素材厚み寸法3.0[mm]以下の物を中心に製品寸法、精度及び材質に応じた帯/コイル圧延機の製作をしております。 ご要求及び製品寸法により可逆式、非可逆式、2/4/6段圧延機、2/4、4/6段組替式圧延機等をご提案させていただきます。

Product 02箔圧延機

製品板厚みが50[μm]以下を製作するための圧延装置です。設備の中には6・12・20段圧延機があり、板圧10[μm]以下の圧延を行う、20段圧延機はロールハウジング構造はゼンジマー型式、ローン型式とは異なり、 4本のポストに支えられた上下方向分離型となっています。これによりロール間隙調整が圧下モーターにより左右独立や同時に行うことが可能になりました。本圧延機に使用する巻取装置は、1台の圧延機で幅広い素材寸法に対応させるため、各張力レンジで使用可能な数種類の機能を持たせた特殊仕様となっております。

Product 03異形/線材圧延装置

丸線から製品(φ相当円/異形断面形状)までの加工をHVに配備した2/3/4方向駆動(非駆動)ロールによって連続的に圧延する圧延装置です。 高速圧延に依る加工熱の影響を軽減させるため、圧延ロール部は油中埋没式も可能としています。出側に配置した非駆動型サイジングロールを使用することにより断面円形状または精密異形断面形状の圧延も可能としています。

Product 04ドローベンチ・伸線機

ドローベンチ・伸線機は丸または異形断面形状の穴ダイスを使用したものと、非駆動形ロールユニット使用の選択ができ、用途に応じて対応が可能です。引抜力は0.1~90tonまでのラインナップがあります。

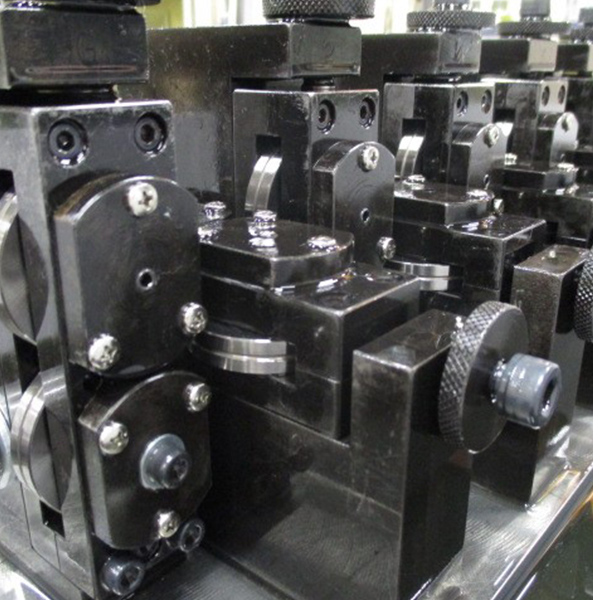

Product 05非駆動型ロールユニット

当社では、ロール配置が2・3・4方向の非駆動型ロールユニットを取扱っております。 多角形からラフラウンド、もしくは丸線、異形断面形状の仕上げ用に使用できます。従来のローラーダイスと比較して、ロール交換時間及び寸法調整の短縮、仕上がり製品精度の向上を果たしております。

Product 06ロールレベラー

ロールレベラーは、駆動・非駆動形素材の剛性に対応させるための可変ピッチタイプなどがあり、必要に応じて対応可能としています。対象素材としては、丸線、無形断面形状、板材などが可能です。

Product 07スエージングマシン

線材の口付け用、ロット材、パイプ等の先端及び段付加工用など様々な製品をお取り扱いしております。

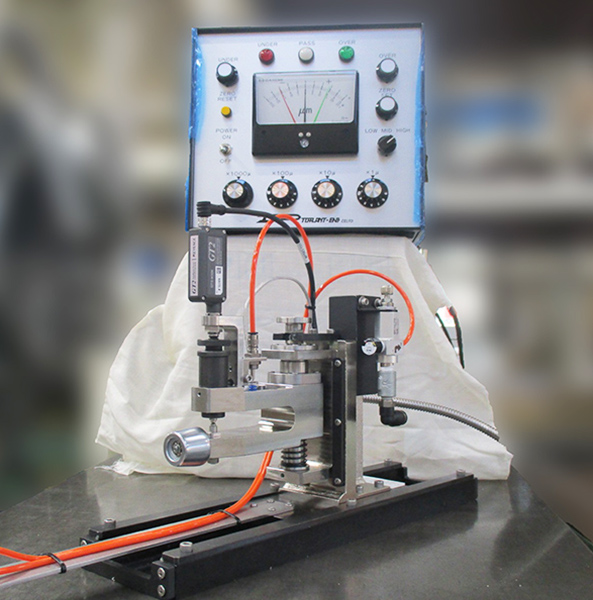

Product 08走行間板厚測定器

圧延中の加工熱を帯びた状態、高速で走り圧延油などの油脂類が多量に付着した製品、及外乱を受けた状態で、厚み/幅を正確に測定できる接触式走行間板圧測定器は、主要部品に低線膨張係数の材料を使用したり、設置環境による温度変化に対応させるため、温度補正を行う機能を有しているので高い精度の測定を可能としています。

製品に接触する測定子は人口ダイヤモンド、W-Coローラータイプがあり測定する製品の形状及精度により選択することができ、更に圧延部の熱影響による製品寸法変化を最小限にするため圧延機と連動して圧延ロール隙間をコントロールさせる自動板厚制御(AGC制御)も可能。